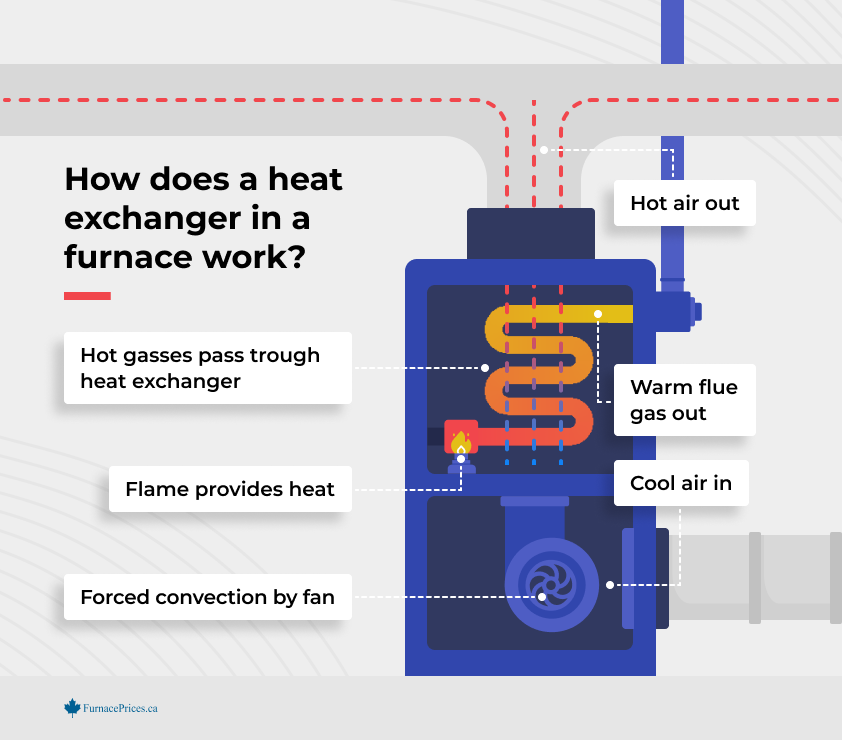

What Is a Heat Exchanger in a Furnace and How Does It Work?

Furnace Heat Exchangers: Understanding Their Importance

Heat Exchangers Are Also Safety Devices

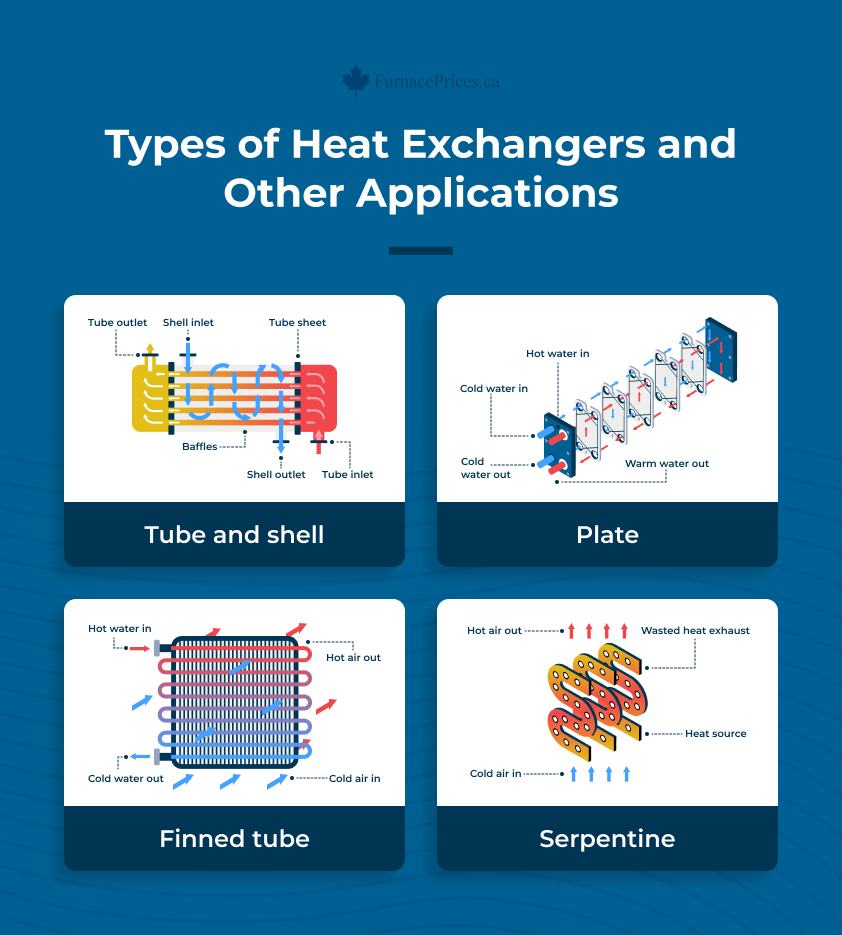

Types of Heat Exchangers and Other Applications

Importance of Heat Exchanger Efficiency

Proprietary Designs and Innovations

- Clamshell: A clamshell heat exchanger is one that doesn’t rely on welds to keep the joints together. This increases longevity by reducing cracking or separating of the joints. Brands that use this design include Lennox, Comfortmaker, Tempstar, and Heil.

- RPJ: This stands for Rigid Press Joint, and it’s a type of clamshell heat exchanger. You can find this component with several furnace brands, including Heil, Tempstar, and Comfortmaker.

- Crimped: This is similar to the clamshell idea, so the joints are crimped together instead of welded to prevent damage from heat stress, improve airflow, and increase durability. This design is available with select Trane and Armstrong (EHX technology) furnaces.

- Turbulators: A turbulator is a device that causes irregular motion of a fluid. When you add a turbulator to a heat exchanger, like Napoleon’s Vortex, it disrupts airflow inside the heat exchanger and recovers more heat from flue gasses.

- Stainless Steel: Some manufacturers like Trane offer stainless steel heat exchangers which may be more durable and longer lasting than aluminium ones.

Get Quotes

How soon are you looking to buy?*

The Benefits of a Secondary Heat Exchanger

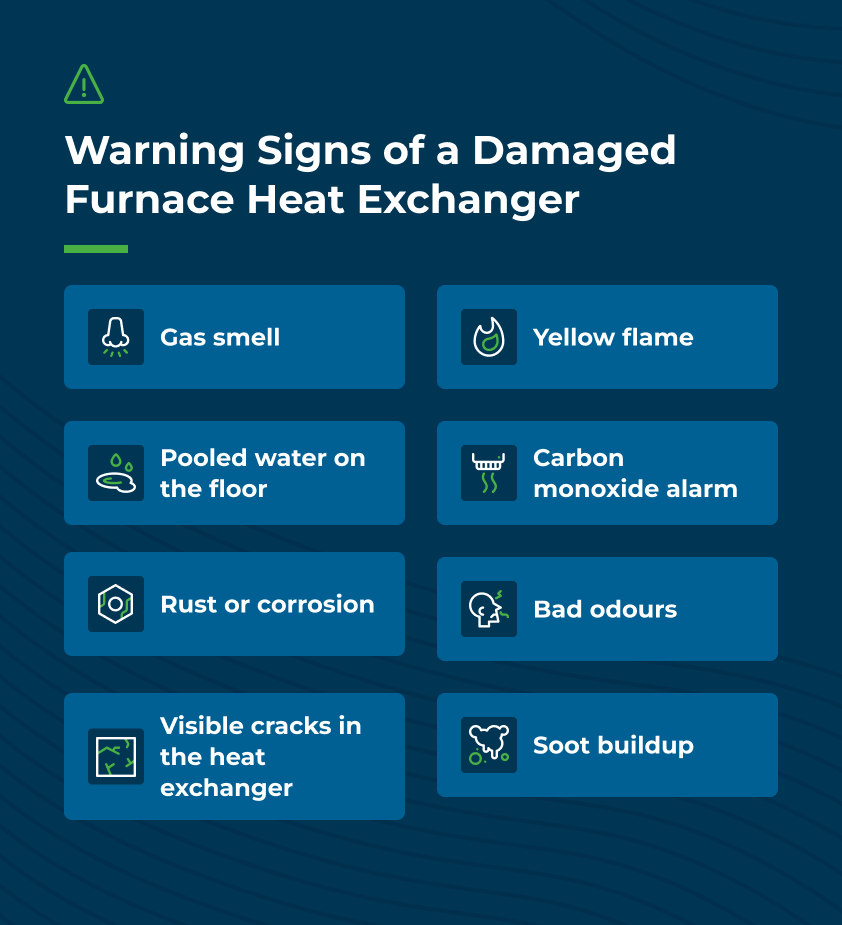

Warning Signs of a Damaged Furnace Heat Exchanger

- The smell of gas (in that case, get your family out of the house and call your utility company or an expert HVAC technician)

- Cracks in the heat exchanger or furnace

- Soot buildup

- Rusty heat exchanger

- Pooled water on the floor

- Change in the flame colour

- Carbon monoxide detector goes off

- Bad odours other than a gas smell

Safety Concerns and Carbon Monoxide Risks

Repairing vs. Replacing Furnace Heat Exchangers: Factors to Consider

How much does it cost to replace a heat exchanger in a furnace?

Repairing a Heat Exchanger Versus Buying a New Furnace or Boiler

Rule #1: Replace Older Models

Rule #2: Repair a Warrantied Heat Exchanger

Rule #3: Upgrade When Repairs Get Too Pricey

Rule #4: Replace Cracked Boiler or Furnace Heat Exchangers

Common Warranty Terms for Heat Exchangers

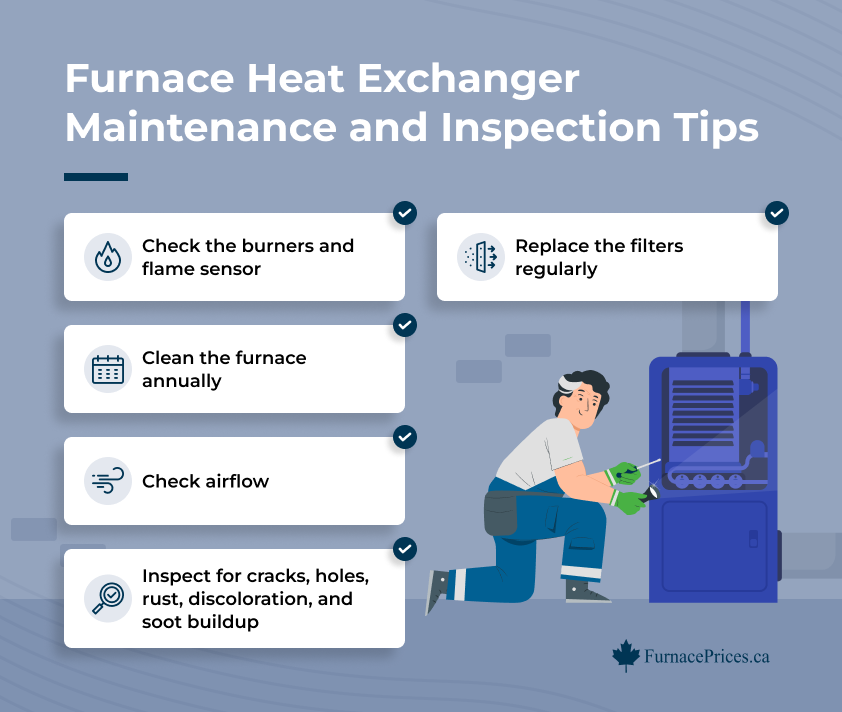

Furnace Heat Exchanger Maintenance and Inspection Tips

DIY vs. Professional Maintenance

Conclusion

FAQ

What is the purpose of a heat exchanger?

Can boiler/furnace heat exchangers be replaced and is it worth it?

What happens when a heat exchanger fails?

Can you run a furnace with a bad heat exchanger?

How many hours does it take to replace a heat exchanger?

What causes a furnace heat exchanger to fail?

Get Quotes

How soon are you looking to buy?*